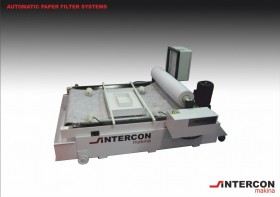

Filter paper fed automatically by reliable level control.

Deep filter-bed, long dryer distance for sludge transfer.

Compact, proven modular construction system.

Optimal filtration and use of filter paper by specially developed attached transport gear.

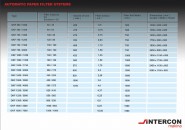

Cost effective standard model range of capacity 30 – 1500 l/min.

Easy sludge evacuation.

Principle of function

The waste liquids flow through the paper. A transport belt with depression through forms an optimal filter bed. The waste from the treated liquid forms a sludge cake.

As the sludge accumulates, the rising liquid level triggers a level sensor which advances the filter paper transport belt. This action brings into use clean paper, and at the same time transfers the sludge cake into a sludge tank, as a result the liquid level falls again.

Utilization / Employment

Continuous liquid cleaning for a large range of applications. Attainable degree of purity, depending on paper, 10 – 50 µ.

Standard model includes

An upper paper-filter-selection with automatic traction and level control,

inlet-case,

Cooland liquid pump,

sludge tank,

liquid tank and one roll of filterpaper.

Accessories

Paper roll cover

Filter bed cover

Castors

Filter paper control

Automatic paper filter combined with magnetic separator

Cooling system.

Automatic paper filter combined with magnetic separator

The magnetic drum rotates against the flow of the waste liquid and separates out the ferromagnetic particles. The precleaned liquid is then passed over the filter paper for final cleaning.

The cleaned liquid is collected in a tank underneath and the ferromagnetic particles are deposited in a sludge tank.

Drive power rating

OKF 500/1000………..OKF 1000/1500 ……. 0,18 kW

OKF 1000/1750………OKF 1000/3000 ……. 0,25 kW

OKF 1000/4000………OKF 1500/7000 ……. 0,37 kW